I research the internet extensively before setting off on my boat projects. Unfortunately, little information was available to document peeling an existing epoxy barrier coat from a fiberglass hull. I thought to document this process on my boat, in order to provide information on what worked, and didn't, to the internet.

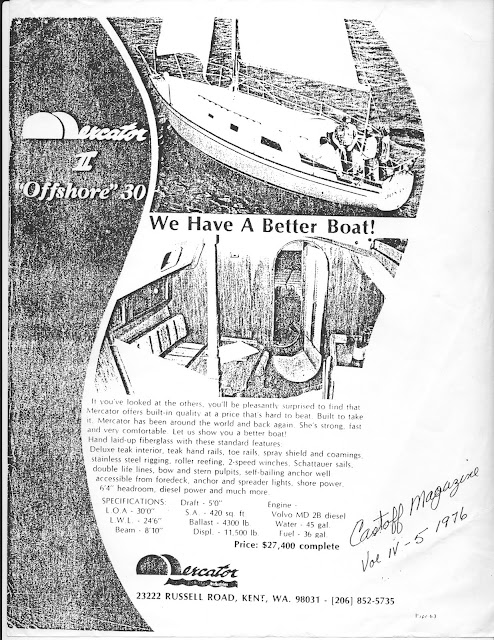

Our boat is a Mercator 30 Mark II, a wonderful fiberglass sailboat hand laid up in Kent, Washington in 1977. The hull is bulletproof. However, many years ago the gelcoat was partially sanded away by someone, and an epoxy barrier coat was applied over a lightweight filler-probably piranha paste or something similar. It is this barrier coat that has now given up, creating thousands of surficial pox. Allowed to go unchecked, this situation will cause water to enter the outer laminate layers, and damage the hull. My solution was to remove the old barrier coat, clean out the surficial blisters, and reapply epoxy in a new barrier layer.

My plan is to bring the hull down to bare fiberglass, remove the blisters, apply two coats of

West System epoxy, then fill and fair with epoxy thickened with lightweight

West System 407 filler, and then two additional coats of epoxy over that. Finally, I will apply two separate coats of bottom paint using two colors, to identify when the outer coat of bottom paint is giving out. Applying filler sandwiched between unthickened epoxy coats, using the same epoxy as base, will probably eliminate the future risk of epoxy failure over filler, as apparently happened in this case.

We hauled in November, and began the process.

Many fiberglass boats received barrier coats in the bad old days of epoxy. I imagine that as time goes by, many of these good old fiberglass boats will start to show failures in the barrier coats applied during the 1980's and later, and will require similar treatment. I hope this record helps all to approach the problem, and learn from my experience.

The first task was to remove bottom paint and epoxy. There is a tool called a

Gelplane that is said to do this fast and efficiently- I looked into purchasing one, but the unit was over 2500 dollars, and not possible to rent.

My yard requires dust extraction into a Shopvac or similar vacuum. Therefore, my arsenal of grinders was not useful. I did look into a plastic dust hood that is made to fit over my

Bosch 4 1/2 inch angle grinder and then attach to a vacuum- but it looked clumsy and not a realistic solution.

Instead, I read reviews of 6 inch random orbital sanders in

FineWoodworking magazine. While many boatyards rely on the

Fein 6 inch sander, the Fine Woodworking review found it overpriced and not efficient. They recommended a two mode sander, where there was a turbo removal and the second mode a random oscillation. For the money, the highest removal rate was achieved by the

Makita BO6040. I bought one from

Toolsforless.com, for a little under 300 bucks- Plus a few bucks for the attachment handle, which later proved invaluable due to the bulkiness and action of this beast. After using it exclusively on turbo mode for the last couple months, I agree with the review- It rips through material, but is very hard to control. I might consider another dual-mode sander like the

Bosch 1250DEVS 6 inch or the

Festool RO 150 next time I have a similar project. I find the Makita tools generally good quality, but often vibrate. I wound up throwing out a Makita 5 inch random orbital sander after too short a time, due to excessive vibration.

I looked into sandpaper options and wound up going with

Festool Brilliant 2 in 40 grit. 36 grit might have been better if I could get it- Brilliant 2 is a closed coat paper- Important to not grind deep into the glass. I bought 2 boxes of 50 sheets each from

Jamestown Distributors for this 30 foot hull and wound up using about 75 total sheets- Changing them often made the sander do the work, not me!

after I had purchased all of this, it occured to me that I might be able to make use of my old

3 x 21 Craftsman belt sander- That epoxy was thick, after all- So I pulled out the belt sander and went at it, much to the amusement of the yard workers-..

I found that going through 2 coats of bottom paint, 4 old layers of epoxy, filler, and primer allowed me to see how deep I was sanding with the belt sander- and gave me sufficient control to remove much of the epoxy without grinding too deep into the fiberglass. There were a few slip ups, but for the time saved by using the belt sander, I recommend at least thinking about the possibility- Remember I was grinding off a barrier coat, not just the gelcoat..

Here are a couple of pictures of the hull after the belt sander-The gray layer is the epoxy- Leaving a little gray meant not going too deep on this first pass. Also, Notice how high I had them block the boat- This provided much better access to the underside during sanding.

Another important piece was that this time, I broke down and bought a

3M full face respirator and

dust cartridges- I can not emphasize how this mask made the whole job bearable- I would come home covered in fiberglass, dust and bottom paint- but my face and lungs were fine- I will never do this kind of work again without this important purchase!

Next, I started systematically removing the bottom paint and epoxy using the 6 inch sander.

Notice the tape set up to protect the waterline. I could sand to within a half inch of the waterline with the orbital sander. The last half inch I removed using a

Bosch 1294 VS corner sander with 60 grit sheets. This corner sander is like the

Fein multimaster at one third the price. Great for sanding edges and corners. I used it extensively around the rudder, skeg and propeller with the different attachments. However, I don't buy the expensive attachment sheets, but just use old sheets of 6 inch 40 grit cut to size with a shear. Works fine.

So that is where this project is at today. I will post information about drying the hull and new throughulls next.